Bottom Hole Pressure Definition

Bottom Hole Pressure (BHP) is a critical parameter in the oil and gas industry, referring to the pressure exerted at the bottom of a wellbore. This pressure is a result of the weight of the fluid column in the well, as well as any additional pressure being applied from the surface or from the reservoir itself. Understanding BHP is essential for drilling, completion, and production operations, as it directly influences the well’s performance, safety, and overall efficiency.

Importance of Bottom Hole Pressure

The measurement and management of BHP are vital for several reasons:

Well Stability and Safety: High BHP can lead to well control issues, potentially causing blowouts if not managed properly. On the other hand, low BHP might result in the influx of formation fluids, which can also compromise well safety.

Reservoir Performance: BHP directly affects the flow of fluids from the reservoir into the wellbore. A decrease in BHP can enhance the flow rate from the reservoir, increasing production, while an increase can reduce it.

Drilling and Completion: Knowledge of BHP is crucial during drilling and completion phases. It helps in designing the well’s trajectory, selecting appropriate casing sizes, and determining the cementing strategy to ensure the well’s integrity and longevity.

Enhanced Oil Recovery (EOR): In EOR techniques, manipulating BHP is a key strategy to increase the recovery factor from mature fields. Maintaining an optimal BHP can help in displacing more oil from the reservoir.

Methods of Measuring Bottom Hole Pressure

Measuring BHP accurately is challenging due to the hostile downhole environment. However, several methods and tools have been developed for its measurement:

Wireline Logging: This involves lowering specialized tools into the well on a wireline to measure various downhole parameters, including pressure and temperature.

Logging While Drilling (LWD): LWD tools measure various properties in real-time as the well is being drilled, providing immediate feedback on downhole conditions, including pressure.

Permanent Downhole Gauges (PDGs): These are installed in the well as part of the completion and provide continuous monitoring of downhole pressure and temperature over the life of the well.

Factors Influencing Bottom Hole Pressure

Several factors can influence BHP, including:

Fluid Density: The density of the fluids in the wellbore affects the hydrostatic pressure exerted at the bottom of the well.

Well Depth: The deeper the well, the higher the hydrostatic pressure due to the weight of the overlying fluid column.

Reservoir Pressure: The natural pressure of the reservoir fluids influences the BHP, especially in production wells.

Surface Pressure: Any pressure applied at the surface, such as during drilling or stimulation operations, can impact BHP.

Managing Bottom Hole Pressure

Effective management of BHP is critical for the success of drilling, completion, and production operations. Strategies for managing BHP include:

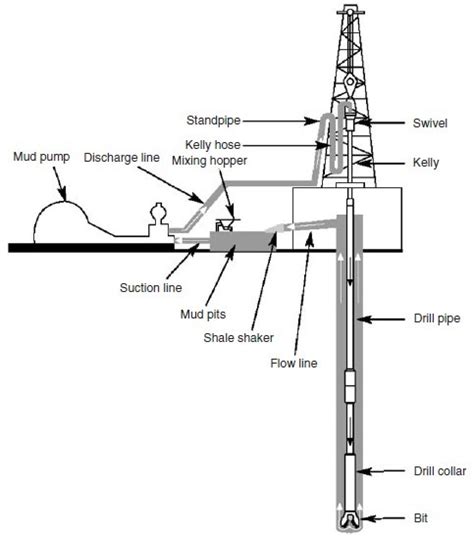

Drilling Mud Weight: Adjusting the density of the drilling mud can help manage BHP and maintain wellbore stability.

Casing Design: The design and placement of casing strings are influenced by BHP considerations to ensure the well’s mechanical integrity.

Artificial Lift: Implementing artificial lift systems can help reduce BHP in producing wells, enhancing flow rates.

Pressure Management During Production: Techniques such as choke management and gas lift can be used to optimize BHP and maximize production rates.

Conclusion

Bottom Hole Pressure is a fundamental parameter in the oil and gas industry, playing a pivotal role in the planning, execution, and optimization of well operations. Its accurate measurement and effective management are crucial for ensuring well safety, optimizing production, and ultimately, the economic viability of oil and gas projects. As the industry continues to evolve, with advancements in measurement technologies and operational strategies, the importance of understanding and managing BHP will only continue to grow.

What is the significance of Bottom Hole Pressure in oil and gas operations?

+Bottom Hole Pressure (BHP) is crucial for the safety, efficiency, and productivity of oil and gas wells. It influences well stability, reservoir performance, and the overall success of drilling, completion, and production operations.

How is Bottom Hole Pressure measured?

+BHP can be measured using various tools and techniques, including wireline logging, Logging While Drilling (LWD), and Permanent Downhole Gauges (PDGs). Each method provides valuable data on downhole conditions, with PDGs offering real-time monitoring over the well’s life.

What factors can influence Bottom Hole Pressure?

+Several factors can influence BHP, including fluid density, well depth, reservoir pressure, and surface pressure. Understanding these factors is key to effective BHP management and optimizing well performance.