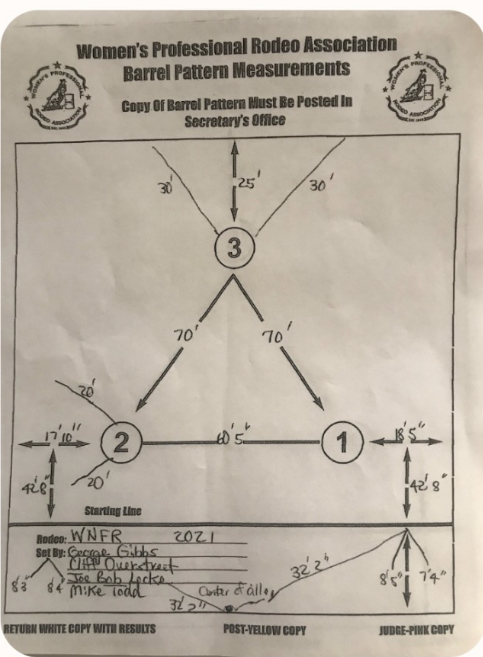

Barrel Pattern Measurements: Accurate Results

The accuracy of barrel pattern measurements is crucial in various fields, including manufacturing, engineering, and quality control. A barrel pattern, also known as a barrel shape or barrel distortion, refers to the curved shape of a cylindrical object, such as a barrel, pipe, or tube. Measuring the dimensions of a barrel pattern requires precise techniques and instruments to ensure accurate results.

One of the primary challenges in measuring barrel patterns is the curved surface, which can make it difficult to obtain accurate measurements using traditional methods. However, with the advancement of technology, various measurement techniques and instruments have been developed to address this challenge. These include:

- Laser scanning: This method uses a laser beam to scan the surface of the barrel and create a 3D model. The 3D model can then be used to extract precise measurements, including the diameter, length, and curvature of the barrel.

- Coordinate measuring machines (CMMs): CMMs use a probe to touch the surface of the barrel at multiple points, creating a map of the surface. The data collected can then be used to calculate the dimensions of the barrel pattern.

- Optical measurement systems: These systems use cameras and software to capture images of the barrel and extract measurements from the images. Optical measurement systems can be used to measure the diameter, length, and curvature of the barrel, as well as detect any defects or irregularities.

To ensure accurate results, it is essential to follow proper measurement procedures and use calibrated instruments. Some best practices for measuring barrel patterns include:

- Using a stable and rigid fixture: The barrel should be securely held in a fixture to prevent movement or vibration, which can affect the accuracy of the measurements.

- Calibrating the measurement instrument: The instrument should be calibrated regularly to ensure that it is functioning correctly and providing accurate results.

- Taking multiple measurements: Multiple measurements should be taken at different points along the length of the barrel to ensure that the results are consistent and accurate.

- Using reference standards: Reference standards, such as calibration artifacts, should be used to verify the accuracy of the measurements.

In addition to these best practices, there are also various standards and specifications that govern the measurement of barrel patterns. These include:

- ASME B89.3.1: This standard provides guidelines for the measurement of cylindrical parts, including barrels.

- ISO 4025: This standard specifies the requirements for the measurement of cylindrical parts, including the use of laser scanning and CMMs.

By following proper measurement procedures and using calibrated instruments, accurate results can be obtained for barrel pattern measurements. These results can be used to ensure that the barrel meets the required specifications and tolerances, which is critical in various industries, including manufacturing, aerospace, and automotive.

When measuring barrel patterns, it is essential to consider the material properties of the barrel, such as its elasticity and thermal expansion. These properties can affect the accuracy of the measurements and should be taken into account when selecting the measurement technique and instrument.

In conclusion, accurate barrel pattern measurements are crucial in various fields, and precise techniques and instruments are required to ensure accurate results. By following best practices, using calibrated instruments, and adhering to standards and specifications, accurate results can be obtained, which can help to ensure the quality and reliability of the barrel.

What is the most accurate method for measuring barrel patterns?

+The most accurate method for measuring barrel patterns is laser scanning, which can provide precise measurements with an accuracy of ±0.01 mm.

What are the common challenges in measuring barrel patterns?

+The common challenges in measuring barrel patterns include the curved surface, which can make it difficult to obtain accurate measurements, and the material properties of the barrel, such as its elasticity and thermal expansion.

What are the benefits of using optical measurement systems for measuring barrel patterns?

+The benefits of using optical measurement systems for measuring barrel patterns include high accuracy, speed, and the ability to detect defects or irregularities. Optical measurement systems can also be used to measure complex shapes and surfaces.